In today’s hyper-connected world, logistics reigns supreme, evolving from mere support to a strategic cornerstone, fueling corporate success and modern economic growth; however, increased efficiency brings escalated risks, where billions in assets and nonstop automated systems are vulnerable to a single electrical fault that could trigger catastrophic supply chain failures.

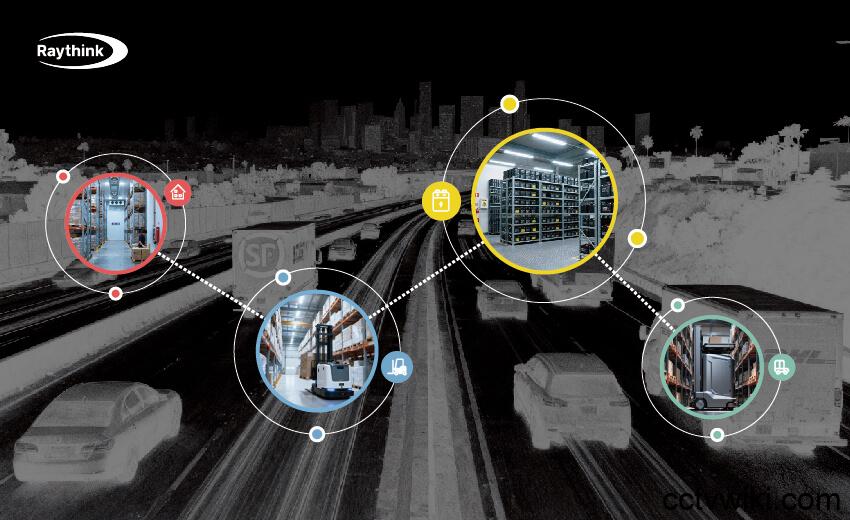

Enter Raythink, with its cutting-edge thermal imaging technology, poised to revolutionize logistics by building resilient, fire-resistant operations, ensuring business continuity, and safeguarding core assets.

The Shortcomings of Traditional Logistics Safety

Modern logistics’ sheer scale and complexity expose the limitations of conventional safety systems, specifically:

* **Blind Spots:** Fixed sensors miss crucial temperature changes in expansive areas.

* **Delayed Detection:** Systems react only to high temperatures or visible smoke, delaying responses to early fire hazards.

* **Environmental Dependence:** Cameras fail in darkness, smoke, or obstructed views.

* **Inaccurate Data:** Traditional tools offer slow, single-point data, missing critical hotspots.

Raythink’s Transformative Approach to Logistics Safety

Raythink’s thermal imaging establishes a comprehensive security system, offering continuous, all-weather monitoring and dual-spectrum fusion for complete coverage and precise temperature analysis throughout warehouses. This system cuts through darkness, dust, and smoke, translating thermal data into actionable insights that form a strong foundation for intelligent safety management.

At the predictive level, the solution continuously analyzes temperature data to build advanced predictive models, transitioning from reactive to proactive safety management. Its multi-dimensional alert system accurately pinpoints abnormal temperature increases and equipment risks, issuing early warnings to prevent operational disruptions.

The VIS-3000 Cloud Platform provides an end-to-end management solution, enabling a complete closed loop from data acquisition and intelligent analysis to multi-terminal coordination. Supporting standard protocol integration and third-party system connectivity, the platform ensures real-time decision-making and supervision through seamless collaboration between the cloud, client, and mobile app.

Customized Thermal Imaging Solutions for Logistics Resilience

Raythink offers tailored thermal imaging solutions for various logistics scenarios:

1. Automated Vertical Storage Solution

By integrating the TN220 or TN430/460 online thermal imager onto stacker cranes or four-way shuttles, the system provides real-time safety monitoring during storage and retrieval, instantly alerting to temperature anomalies.

2. Manual Warehousing Solution

For digital warehouses with manual operations, Raythink employs a hybrid strategy combining fixed-position defense with dynamic patrol inspections. Deploying PD225T and FC2/FC4 dual-spectrum cameras ensures continuous monitoring and periodic scans. This solution offers real-time temperature anomaly detection and integrates advanced AI algorithms for smoke detection, fire source identification, and personnel behavior analysis, ensuring comprehensive and intelligent safety oversight.

3. Special Goods Warehousing Supervision

For temperature-sensitive and high-risk goods like food, pharmaceuticals, and lithium batteries, Raythink’s thermal imaging system ensures quality protection, early risk warnings, and energy efficiency.

For instance, in lithium battery warehouses, compact TN220 thermal cameras work with stacker arms for 24/7 monitoring of high-rise shelving, detecting thermal runaway early and triggering instant alerts. In high-risk zones like electrolyte storage rooms, explosion-proof TE365 thermal imagers provide continuous monitoring, automatically alerting the control center to temperature anomalies and enabling rapid, closed-loop risk response.

4. Sorting & Distribution Centers

High-speed sorting lines and automated equipment are prone to overheating due to friction or motor overload, potentially causing equipment failure or fire. Raythink’s online thermal imaging cameras enable non-contact temperature monitoring of critical components, accurately identifying heat spots. This transforms maintenance into proactive prevention, avoiding unplanned shutdowns and ensuring business continuity through early fire detection.

The Future of Smart Logistics: Safety and Efficiency Combined

By integrating continuous thermal perception, AI-driven analytics, and end-to-end cloud intelligence, Raythink’s thermal imaging empowers logistics enterprises to protect their assets, maintain uninterrupted operations, and build trust across the supply chain.

In a world where every second and every link counts, Raythink illuminates the path towards a fire-free, interruption-free logistics future where safety and efficiency advance together.

Learn More

Discover how Raythink can transform your logistics operations by visiting the official Raythink website.